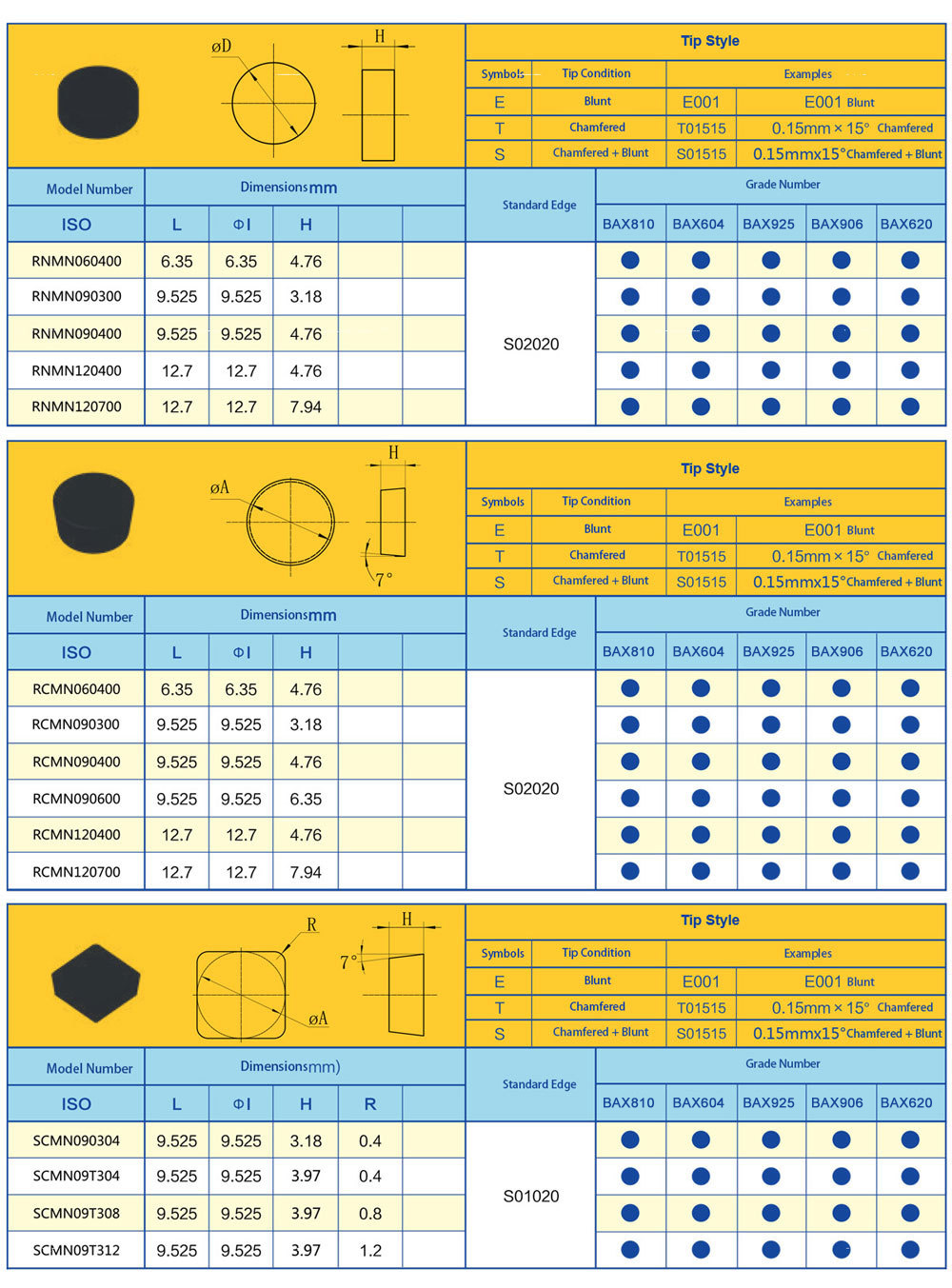

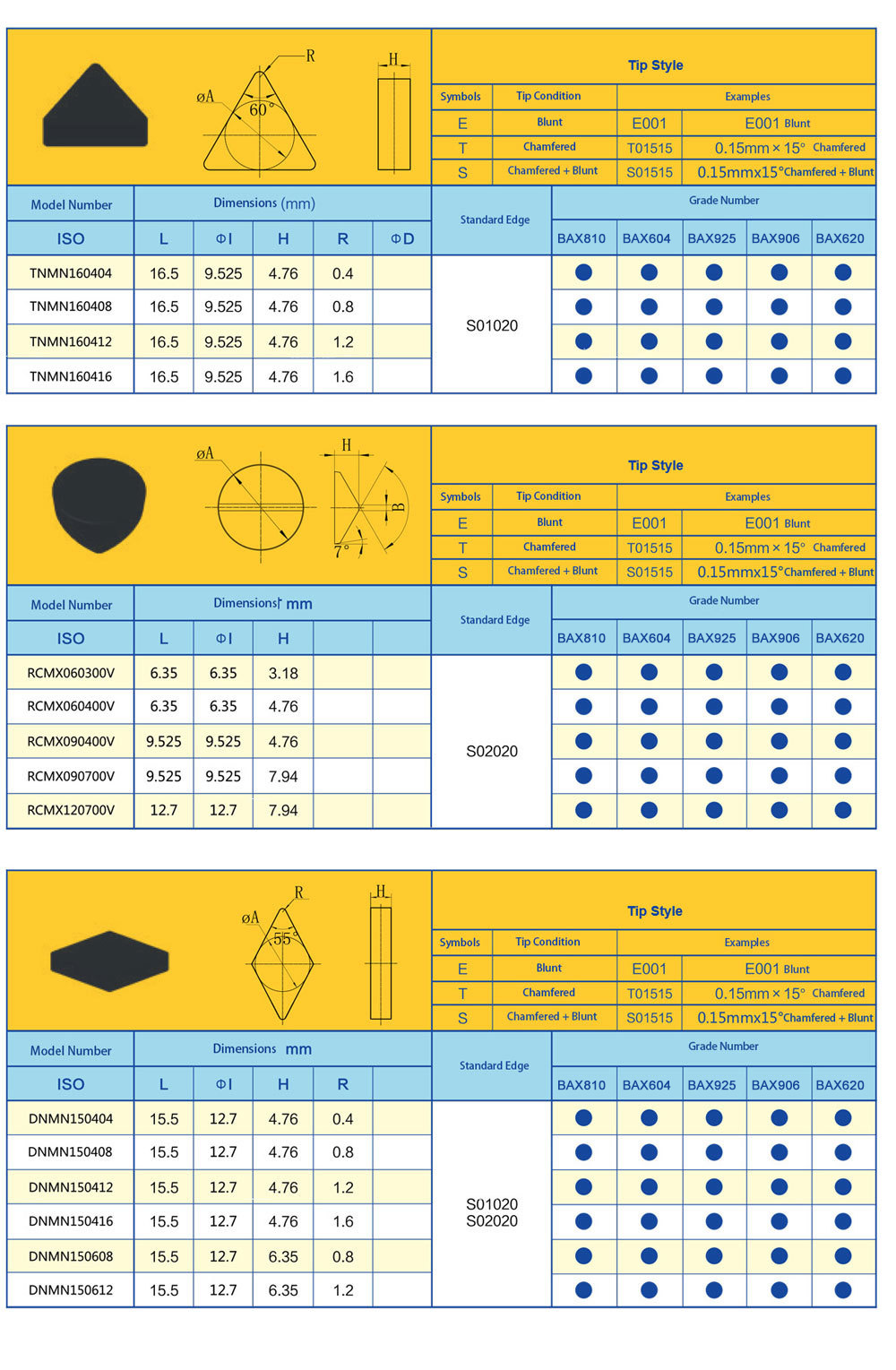

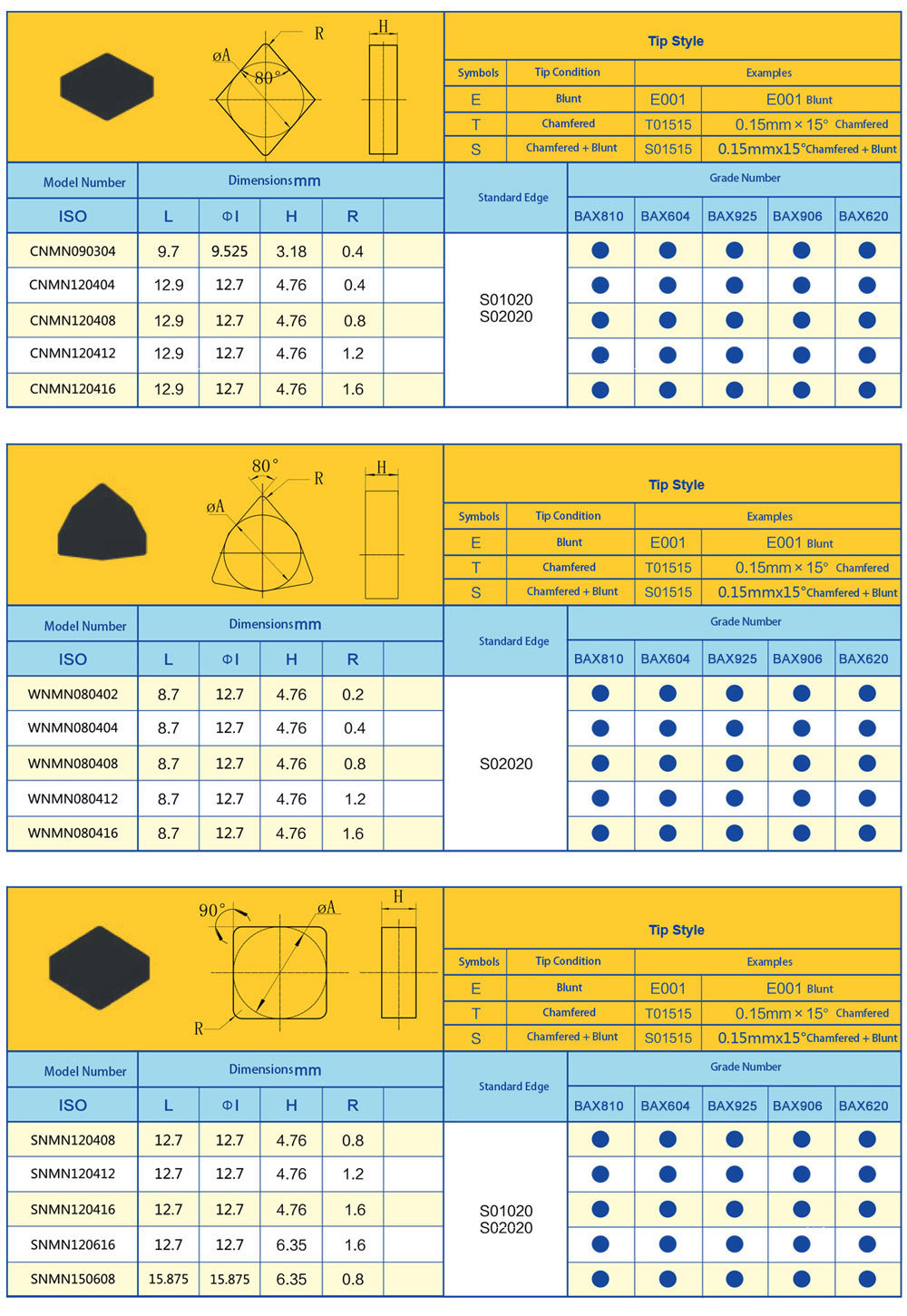

PCBN/PCD Inserts - Z Series(Solid CBN Inserts )

● For rough/semi-finish machining

● Superior impact resistance and capability for large cutting depths

● Capable of high-speed cutting with long tool life

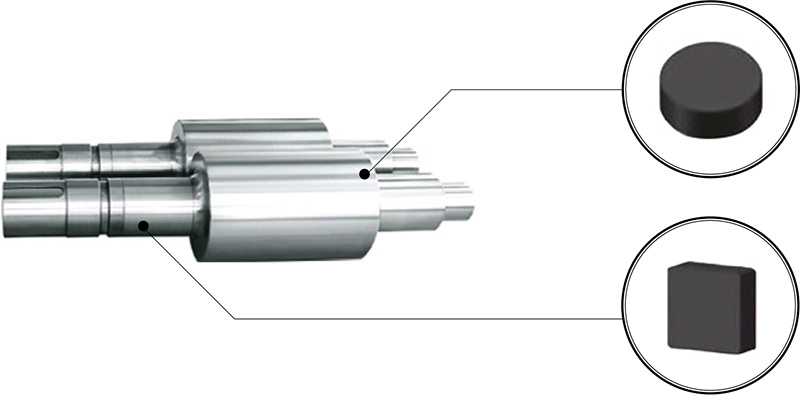

PCBN Altrahard Tools- Application Case 1

● Tool Selection

PCBN monolithic sintered blades

● Machining Object

Roller outer diameter

● Machining Process and Results

Turning: With 8mm roughing allowance, PCBN blades remove material quickly. During finishing, their excellent wear and impact resistance guarantee precision and surface quality, greatly boosting efficiency.

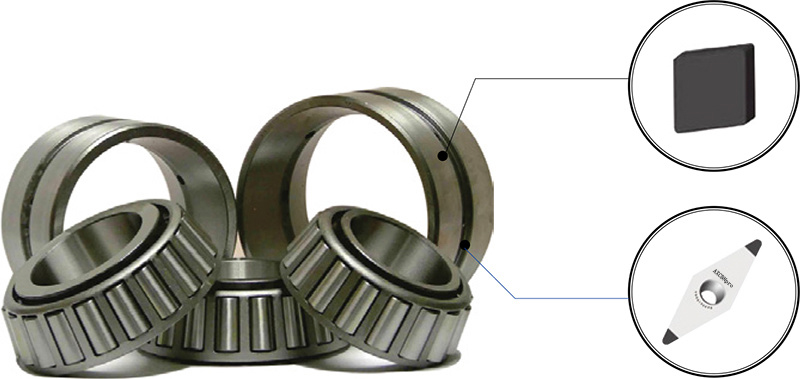

PCBN Altrahard Tools- Application Case 2

● Tool Selection

PCBN blades

● Machining Object

The raceway of slewing bearings

● Machining Process and Results

Hard turning (finish machining): Achieves "turning instead of grinding" with a surface roughness of Ra < 0.8μm. The machining efficiency is increased by more than 5 times compared to grinding, significantly reducing costs and improving efficiency.

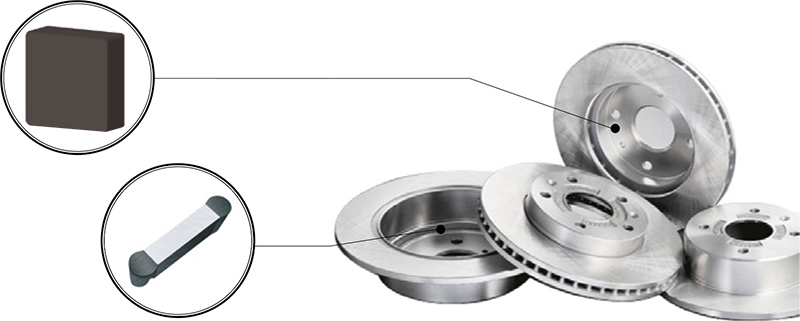

PCBN Altrahard Tools- Application Case 3

● Tool Selection

PCBN blades

● Machining Object

End face, outer diameter, and inner hole of cast iron brake discs

● Machining Process and Results

Rough turning: Machining allowance of 3mm. PCBN blades efficiently operate under harsh conditions with extremely high impact resistance, wear resistance, and metal removal rate, enabling rapid removal of large amounts of material.

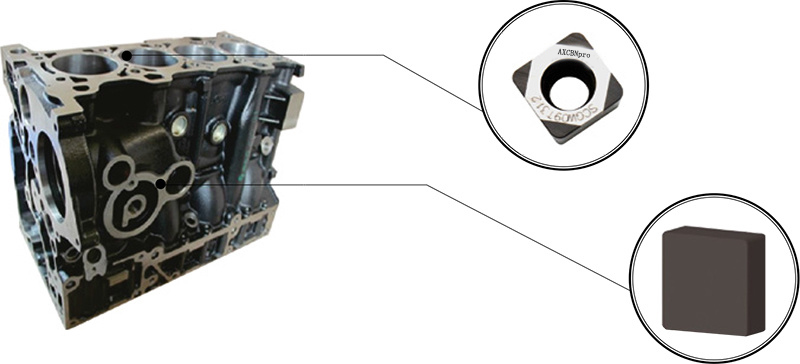

PCBN Altrahard Tools- Application Case 4

● Tool Selection

PCBN blades

● Machining Object

Cylinder bores of cylinder blocks

● Machining Process and Results

Semi-finishing and finishing via boring:The multi-cutting-edge design of PCBN blades enhances cost-effectiveness, achieving 3× higher machining efficiency and 5× longer tool life compared to conventional coated blades

● Tool Selection

PCBN blades

● Machining Object

Assembly surfaces of cylinder blocks

● Machining Process and Results

Semi-finishing and finishing via face milling: PCBN blades deliver unmatched workpiece surface quality and doubled machining efficiency.

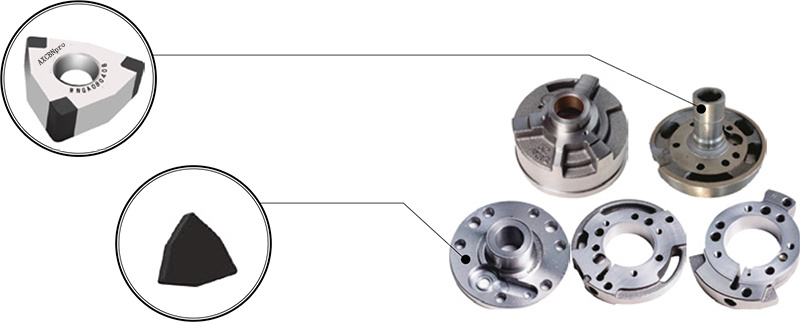

PCBN Altrahard Tools- Application Case 5

● Tool Selection

PCBN blades

● Machining Object

End faces and outer diameters of cast iron parts for air conditioner compressors

● Machining Process and Results

Rough/finish turning and boring: Models 925A & 960A enable large cutting depths, achieving 10% higher efficiency and over 15% longer tool life than comparable tools, ensuring economic stability.

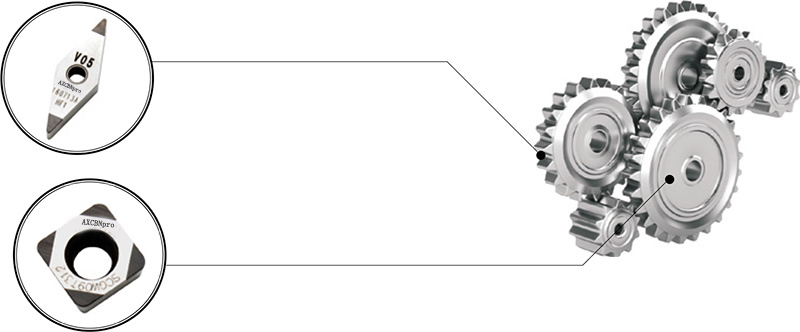

PCBN Altrahard Tools- Application Case 6

● Tool Selection

PCBN brazed blades

● Machining Object

End faces, outer diameters of gear components, and bearing raceways

● Machining Process and Results

Alloy steel, high-speed steel, hardened steel:Models 604C and 1007/1008 are engineered for gear applications, delivering high-speed, high-efficiency performance with exceptional comprehensive properties.

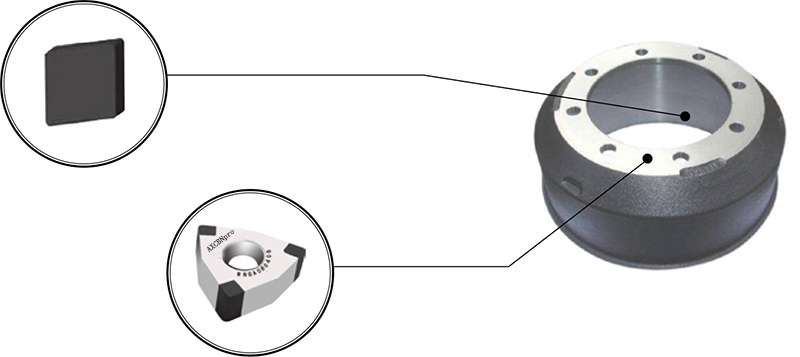

PCBN Altrahard Tools- Application Case 7

● Tool Selection

PCBN blades

● Machining Object

Cast iron brake drum inner hole

● Machining Process and Results

Turning: Roughing and finishing operations completed in a single setup, ensuring superior surface quality while streamlining production efficiency.

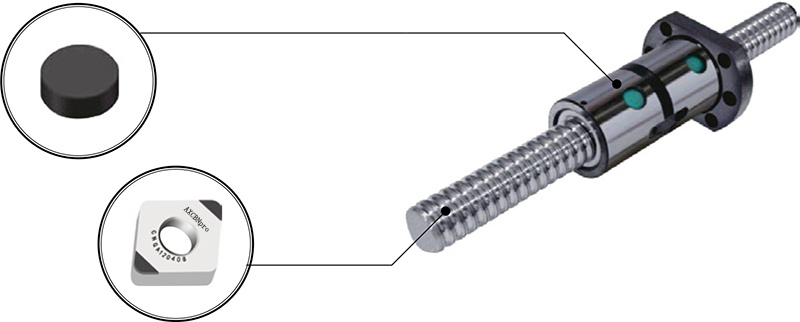

PCBN Altrahard Tools- Application Case 8

● Tool Selection

PCBN blades

● Machining Object

Thread grooves of lead screws

● Machining Process and Results

Turning: Rough machining of thread profiles.

First in China: Application of PCBN inserts for roughing thread grooves, achieving significant improvements in machining efficiency and reduced production costs.

PCBN Altrahard Tools- Application Case 9

● Tool Selection

PCBN blades

● Machining Object

Outer diameter water seal groove, outer diameter, inner diameter, and relief groove

● Machining Process and Results

Turning: Grooving and finishing

Boring: Finishing

Enhanced Tool Life & Machining Efficiency: 3× faster processing than coated inserts, with significantly prolonged tool life and reduced surface roughness.

Superior Machining Performance: Low cutting force and excellent cylindricity control.

Non-standard formed blades also feature high precision and high efficiency.

Pre:Welded Inserts

Next:Grooving Inserts